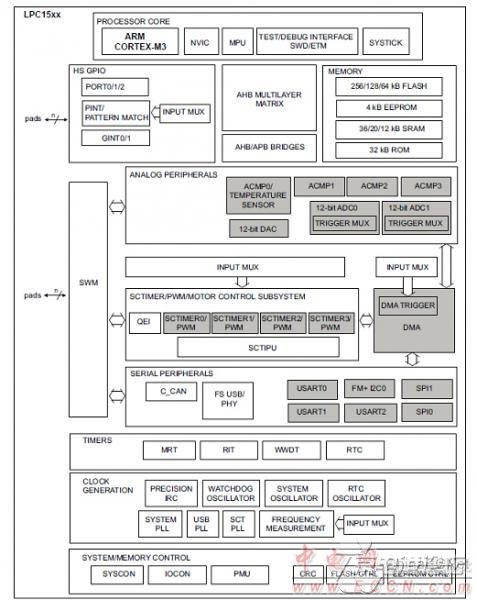

NXP公司的LPC15xx系列是基于72MHz的ARM Cortex-M3内核的MCU,接纳三级流水线和哈佛架构,集成了256KB闪存,32KB ROM,4KB EEPROM和多达36KB SRAM,以及多种外设,主要用在嵌入应用如马达控制,太阳能逆变器,家用电器,医疗设备,修建物和工厂自动化,数字电源.本文先容了LPC15xx主要特点,框架图和LPCXpressoBLDC马达控制板主要特点和电路图.

The LPC15xx are ARM Cortex-M3 based microcontrollers for embedded applications featuring a rich peripheral set with very low power consumption. The ARM Cortex-M3 is a next generation core that offers system enhancements such as enhanced debug features and a higher level of support block integration.

The LPC15xx operate at CPU frequencies of up to 72 MHz. The ARM Cortex-M3 CPU incorporates a 3-stage pipeline and uses a Harvard architecture with separate local instruction and data buses as well as a third bus for peripherals. The ARM Cortex-M3 CPU also includes an internal prefetch unit that supports speculative branching.

The LPC15xx includes up to 256 kB of flash memory, 32 kB of ROM, a 4 kB EEPROM,and up to 36 kB of SRAM. The peripheral complement includes one full-speed USB 2.0 device, two SPI interfaces, three USARTs, one Fast-mode Plus I2C-bus interface, one C_CAN module, PWM/timer subsystem with four configurable, multi-purpose State Configurable Timers (SCTimer/PWM) with input pre-processing unit, a Real-time clock module with independent power supply and a dedicated oscillator, two 12-channel/12-bit,2 Msamples/s ADCs, one 12-bit, 500 kSamples/s DAC, four voltage comparators with internal voltage reference, and a temperature sensor. A DMA engine can service most peripherals.

LPC15xx主要特点:

System:

ARM Cortex-M3 processor (version r2p1), running at frequencies of up to 72 MHz.

ARM Cortex-M3 built-in Nested Vectored Interrupt Controller (NVIC).

System tick timer.

Serial Wire Debug (SWD) with four breakpoints and two watchpoints.

Single-cycle multiplier supported.

Memory Protection Unit (MPU) included.

Memory:

Up to 256 kB on-chip flash programming memory with 256 Byte page write anderase.

Up to 36 kB SRAM.

4 kB EEPROM.

ROM API support:

Boot loader with boot options from flash or external source via USART, C_CAN, orUSB

USB drivers

ADC drivers

SPI drivers

USART drivers

I2C drivers

Power profiles and power mode configuration with low-power mode configurationoption

DMA drivers

C_CAN drivers

Flash In-Application Programming (IAP) and In-System Programming (ISP).

Digital peripherals:

Simple DMA engine with 18 channels and 20 programmable input triggers.

High-speed GPIO interface with up to 76 General-Purpose I/O (GPIO) pins with configurable pull-up/pull-down resistors, open-drain mode, input inverter, andprogrammable digital glitch filter.

GPIO interrupt generation capability with boolean pattern-matching feature on eight external inputs.

Two GPIO grouped port interrupts.

Switch matrix for flexible configuration of each I/O pin function.

CRC engine.

Quadrature Encoder Interface (QEI).

Configurable PWM/timer/motor control subsystem:

Up to four 32-bit counter/timers or up to eight 16-bit counter/timers or combinations

of 16-bit and 32-bit timers.

Up to 28 match outputs and 22 configurable capture inputs with input multiplexer.

Up to 28 PWM outputs total.

Dither engine for improved average resolution of pulse edges.

Four State Configurable Timers (SCTimers) for highly flexible, event-driven timing

and PWM applications.

SCT Input Pre-processor Unit (SCTIPU) for processing timer inputs and immediate handling of abort situations.

Integrated with ADC threshold compare interrupts, temperature sensor, and analog comparator outputs for motor control feedback using analog signals.

Special-application and simple timers:

24-bit, four-channel, multi-rate timer (MRT) for repetitive interrupt generation at up to four programmable, fixed rates.

Repetitive interrupt timer for general purpose use.

Windowed Watchdog timer (WWDT).

High-resolution 32-bit Real-time clock (RTC) with selectable 1 s or 1 ms time resolution running in the always-on power domain. RTC can be used for wake-up from all low power modes including Deep power-down.

Analog peripherals:

Two 12-bit ADC with up to 12 input channels per ADC and with multiple internal and external trigger inputs and sample rates of up to 2 Msamples/s. Each ADC supports two independent conversion sequences. ADC conversion clock can be the system clock or an asynchronous clock derived from one of the three PLLs.

One 12-bit DAC.

Integrated temperature sensor and band gap internal reference voltage.

Four comparators with external and internal voltage references (ACMP0 to 3).Comparator outputs are internally connected to the SCTimer/PWMs and ADCs and externally to pins. Each comparator output contains a programmable glitch filter.

Serial interfaces:

Three USART interfaces with DMA, RS-485 support, autobaud, and with

synchronous mode and 32 kHz mode for wake-up from Deep-sleep and

Power-down modes. The USARTs share a fractional baud-rate generator.

Two SPI controllers.

One I2C-bus interface supporting fast mode and Fast-mode Plus with data rates of up to 1Mbit/s and with multiple address recognition and monitor mode.

One C_CAN controller.

One USB 2.0 full-speed device controller with on-chip PHY.

Clock generation:

12 MHz internal RC oscillator trimmed to 1 % accuracy for 25 C Tamb +85 Cthat can optionally be used as a system clock.

Crystal oscillator with an operating range of 1 MHz to 25 MHz.

Watchdog oscillator with a frequency range of 503 kHz.

32 kHz low-power RTC oscillator with 32 kHz, 1 kHz, and 1 Hz outputs.

System PLL allows CPU operation up to the maximum CPU rate without the need for a high-frequency crystal. May be run from the system oscillator or the internalRC oscillator.

Two additional PLLs for generating the USB and SCTimer/PWM clocks.

Clock output function with divider that can reflect the crystal oscillator, the mainclock, the IRC, or the watchdog oscillator.

Power control:

Integrated PMU (Power Management Unit) to minimize power consumption.

Reduced power modes: Sleep mode, Deep-sleep mode, Power-down mode, and

Deep power-down mode.

APIs provided for optimizing power consumption in active and sleep modes and for configuring Deep-sleep, Power-down, and Deep power-down modes.

Wake-up from Deep-sleep and Power-down modes on activity on USB, USART,

SPI, and I2C peripherals.

Wake-up from Sleep, Deep-sleep, Power-down, and Deep power-down modes

from the RTC alarm or wake-up interrupts.

Timer-controlled self wake-up from Deep power-down mode using the RTC

high-resolution/wake-up 1 kHz timer.

Power-On Reset (POR).

BrownOut Detect BOD).

JTAG boundary scan modes supported.

Unique device serial number for identification

Single power supply 2.4 V to 3.6 V.

Temperature range 40 ℃ to +105 ℃.

Available as LQFP100, LQFP64, and LQFP48 packages.

LPC15xx系列应用:

Motor control

Solar inverters

Motion drives

Home appliances

Digital power supplies

Building and factory automation

Industrial and medical

图1{京电港论坛}。LPC15xx系列框架图

LPC1549 LPCXpressoBLDC马达控制板

The LPCXpresso Motor Control Kit makes it possible for you to get started with motor control prototyping immediately.It is a platform for low voltage motor control based on NXP’s MCUs. With this universal platform it is possible to control BLDC, BLAC, stepper and dual brushed DC motors.

图2{京电港论坛}。LPC1549 LPCXpressoBLDC马达控制板外形图

LPC1549 LPCXpressoBLDC马达控制板主要特点:

LPC1549 ARM Cortex-M3 based microcontroller

256 kB of flash memory, 32 kB of ROM, 4 kB EEPROM, and up to 36 kB of SRAM

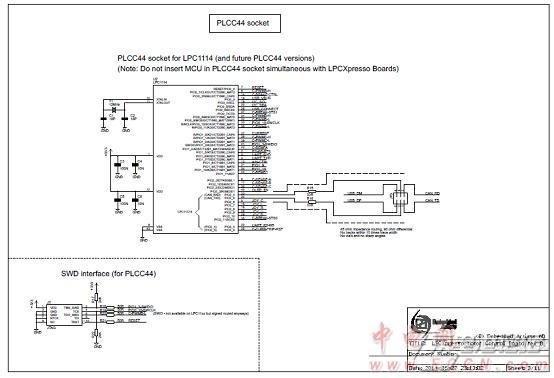

Socket for LPC1xxx in PLCC44

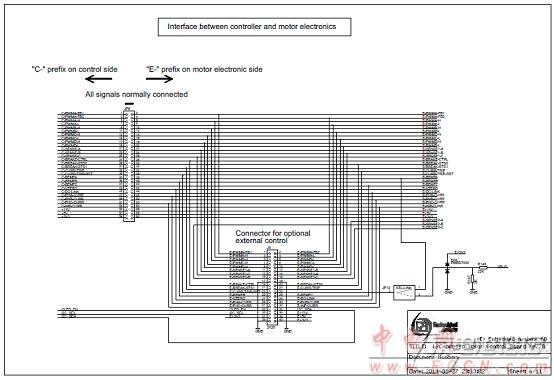

Expansion connector for control by LPC1800/LPC4000/LPC2900 families, or other 4 phases (based on NXP PSMN2R6-40YS N-channel MOSFET), accessed via screw terminals

Phase control support 100 % duty cycle

Voltage measurement (on three phases and virtual ground)

Current measurement (on three phases and common low-side)

Input current measurement, including over-current trip

Break functionality

Hall & QEI sensor inputs, connected via screw terminals

Temperature sensor

12 - 30 V input voltage, 17 A max. current (max. 300 W output)

On-board 15 W power supply (+11 V, +5 V, +3.3 V)

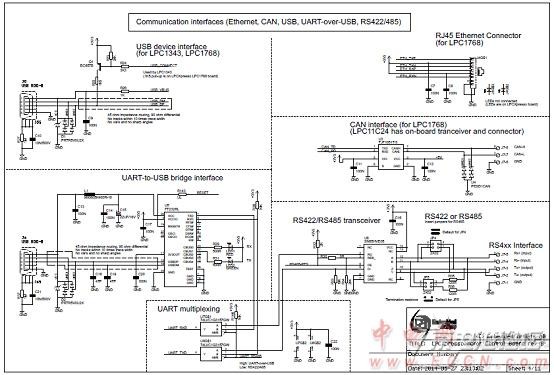

USB interface (must be supported by controlled MCU)

Ethernet interface (must be supported by controlled MCU)

CAN interface (must be supported by controlled MCU)

RS422/485 interface

UART-to-USB interface

5-key joystick switch

96 x 64 pixel OLED

Reset pushbutton

I²C-E2PROM

SWD/JTAG connector

2.1 mm input jack, or via screw terminals

12 - 30 V, 17 A max.

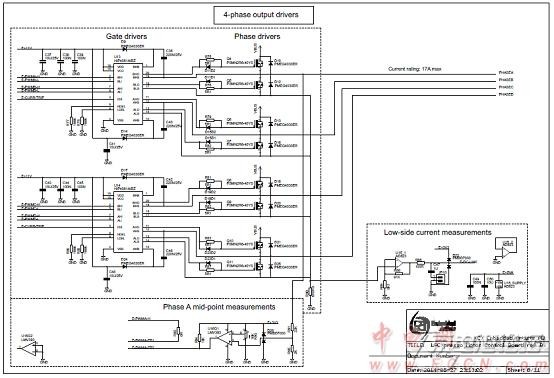

图3{京电港论坛}。LPC1549 LPCXpressoBLDC马达控制板电路图(1)

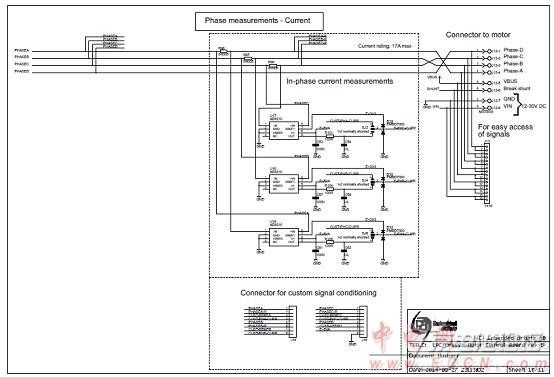

图4{京电港论坛}。LPC1549 LPCXpressoBLDC马达控制板电路图(2)

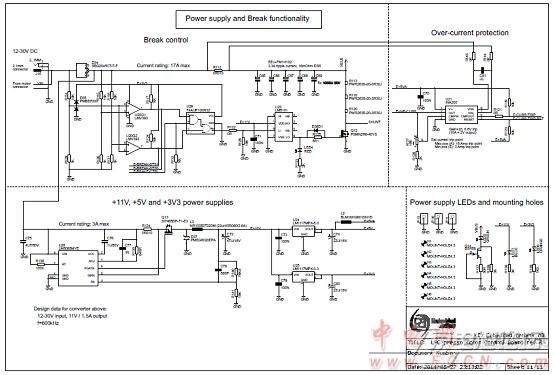

图5{京电港论坛}。LPC1549 LPCXpressoBLDC马达控制板电路图(3)

图6{京电港论坛}。LPC1549 LPCXpressoBLDC马达控制板电路图(4)

图7{京电港论坛}。LPC1549 LPCXpressoBLDC马达控制板电路图(5)

图8{京电港论坛}。LPC1549 LPCXpressoBLDC马达控制板电路图(6)

图9{京电港论坛}。LPC1549 LPCXpressoBLDC马达控制板电路图(7)

图1{京电港论坛}0。LPC1549 LPCXpressoBLDC马达控制板电路图(8)

图1{京电港论坛}1。LPC1549 LPCXpressoBLDC马达控制板电路图(9)

图1{京电港论坛}2。LPC1549 LPCXpressoBLDC马达控制板电路图(10)

详情请复制打开此衔接地址:

http://www.nxp.com/documents/data_sheet/LPC15XX.pdf

和http://www.nxp.com/documents/user_manual/UM10736.pdf

以及http://www.nxp.com/documents/other/LPCXpresso_Motor_Control_Kit_UserManual.pdf

LPC15XX.pdf

LPC15XX.pdf

UM10736.pdf

UM10736.pdf